Double Glazing (Columbia)

Insulating Glazing Assemblies - Description

These are sealed units comprising two panes of glass which, having been assembled and sealed in the factory, are separated by a closed hermetic space containing air or an insulating gas. The main aim of such assemblies is to use the insulating properties of the air or gas space to lower the thermal transmittance (Ug value) of the glazing. The latter's insulating properties can be further enhanced in various ways (low-emissivity coatings, gas and so on). The unit may be double- or triple-glazed.

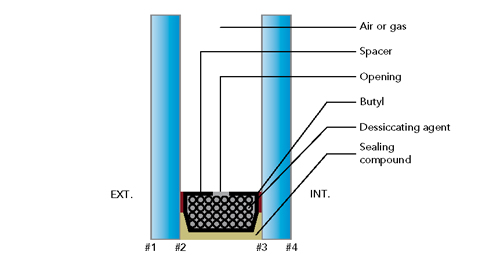

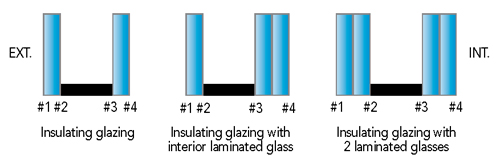

Insulating glazing: components and numbering of the sides

The sides of insulating glazing are generally numbered positions 1 to 4 from the outside in, the outside being on the left in the diagram below.

Numbering of the sides of insulating glazing

The composition of a sealed unit is shown by three figures (in mm) representing the following thicknesses:

- The pane of external glass

- The air or gas space

- The internal pane of glass

Example: 6/12/4 indicates a pane of external glass 6 mm thick, a spacer measuring 12 mm and an internal pane of glass 4 mm thick.

Double Glazing Components

Double glazing comprises the following elements:

- Two panes of glass

- A spacer to determine the width of the space between the two panes of glass

- The space between the two panes of glass may be filled with air or with another gas injected during the manufacturing process (argon or krypton)

- An initial waterproof barrier made of butyl and positioned on the side of the spacer which is in contact with the glass. It is designed to prevent moisture from entering the air or gas space

- A second waterproof barrier or seal linking the panes of glass and the spacer. This is designed to ensure that the assembly is mechanically stable; the seal is made of either polysulphide, polyurethane or silicone. Only silicone is suitable if the seal will be exposed to solar radiation or in some specific applications

- A desiccant placed in the spacer to dry out (adsorb) the gas trapped at the point at which the glass touches and to adsorb steam which may enter the unit over time through the outside seal

How well the desiccant and the waterproof barriers function will determine how the long the unit lasts; if the desiccant becomes ineffective or if the seal is no longer hermetic, condensation will form inside the unit and it will have to be replaced.

Metalco offers two possible joint technologies (polysulphide, silicone) and spacer bar types (alu, steel Warm E). Metalco also offers the unique possibility to combine silicone with an argon filling or even a Warm E spacer.

Height

Double-glazing units to travel through or to be fitted 800 m higher in relation to the production location will either be levelled out in advance in the workshop or will be fitted with a levelling mechanism. It is important to specify this when placing your order.